Optical Micrometer / Digital Micrometer

Similar to laser micrometers, optical micrometers are thrubeam sensors that measure any object that blocks the light passing from the transmitter to receiver. These sensors are designed without moving parts to provide accurate measurement without regular maintenance. KEYENCE’s optical micrometers come in single-axis, multi-axis, or 2D models (that create 2D backlit images). Micrometers are ideal for measuring diameter, gap, and width with high accuracy.

Products Lineup

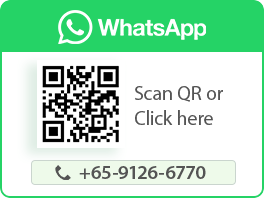

TM-3000 Series high-speed 2D optical micrometers were the first in the world to enable calibrated backlit measurement. They can be used both inline and offline to simultaneously complete measurements in the X- and Y-axis, such as outer diameters and height differences. The high-intensity LED and dual telecentric optical system provide highly repeatable results that are unaffected by external lighting. Maximum outer diameters, angles, etc., can be measured instantly because areas, not points, are measured. The part's position is detected, and measurements are automatically adjusted to the proper location, enabling accurate measurements. The system is capable of 15 types of basic measurement modes and 8 types of auxiliary measurement modes, providing a robust solution for a wide variety of applications.

Features

Outer diameter and step measurements of multiple points can be performed at the same time, which reduces the takt time.

The dimensions of up to 16 locations can be measured at the same time from the acquired silhouette.

Moving targets can also be measured with no blurring.

Even though this is an optical comparator, the high-speed sampling and position correction function enable stable inline measurement.

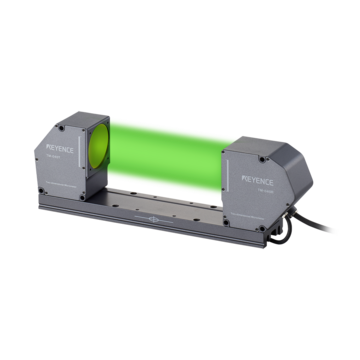

LS-7000 Series high-speed, high-accuracy digital micrometers use our proprietary optical system with no moving parts to provide a measurement solution with high speed, accuracy, and durability. Conventional laser scanning micrometers drive a polygon mirror with a motor to measure parts. In contrast, the optical system of the LS-7000 Series uses a high-intensity GaN green LED light source, telecentric lenses, and an HL-CCD to deliver high performance over the lifespan of the sensor without constant maintenance or recalibration. Additionally, the system is equipped with a built-in monitor CMOS that displays the target within the measurement range, making it easy to check the measurement location or adjust the position of the target as necessary.

Features

Designed without Moving Parts for Longer Lifespan and Less Maintenance

KEYENCE’s proprietary optical design has no moving parts, eliminating the need for recalibration and long term maintenance.

Achieve High-Accuracy Measurement in-Line

Increased sampling speed makes high-accuracy measurement possible on moving targets, as well as still targets.

IG Series multi-purpose CCD laser micrometers provide high-precision differentiation that is unaffected by how much light the target transmits. This series uses a line-charge coupled device (L-CCD) as its light-receiving element. Instead of using received light intensity, it captures the edge of transmitted laser light, so it can perform high-accuracy, stable differentiation with 5 μm repeatability and ±0.1% linearity. This makes the IG Series capable of supporting various applications, including edge detection and positioning of clear glass, precise recognition of workpiece OD, feedback control while detecting a sheet edge, and roll gap measurement. The positioning monitor on the main unit facilitates optical-axis alignment when starting up a line and during changeovers.

Features

Easy to Use

The position monitor makes it easier to align the optical axis. Easily perform optical axis alignment by adjusting the sensor head so that all of the position monitor lights turn red.

Environmental Resistance

The enclosure satisfies the IP67 rating based on the IEC standards and remains watertight even after being held at a depth of one meter for 30 minutes. The enclosure is resistant to adverse environments and offers long-term durability.

IB Series thrubeam-type laser detection sensors cater to a diverse range of applications by differentiating received light intensity with high accuracy. This series uses a photodiode (PD) for its light-receiving element. By accurately detecting the changes in received light intensity, it can support various applications without being affected by the target. For example, the IB Series can be used for applications that are impossible with photoelectric sensors, such as the detection of liquid crystal glass and liquid turbidity, differentiation of film types, tilt detection of chips, and incorrect seating of caps, all at low cost. The compact sensor head is equipped with an alignment LED, so optical-axis alignment is easy.