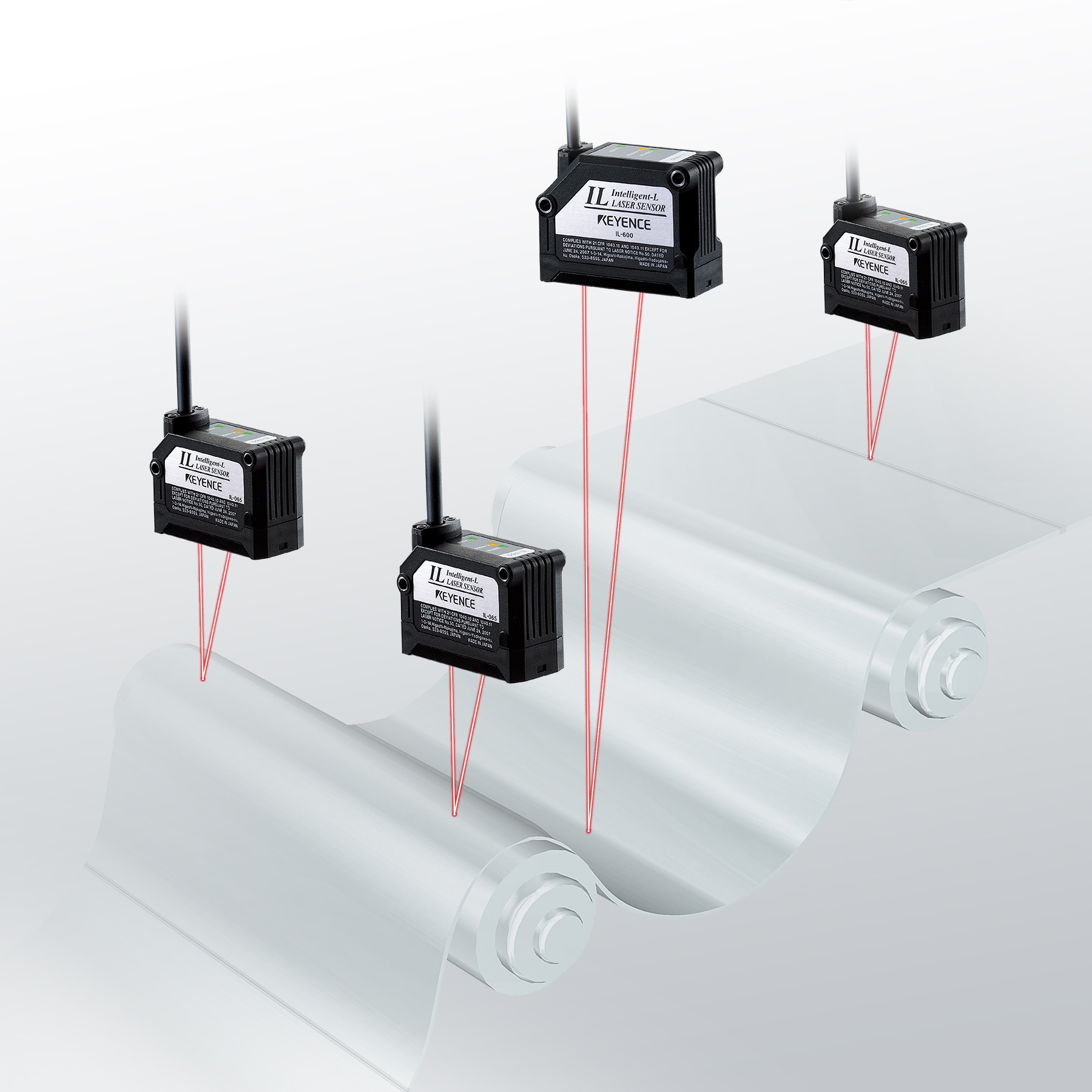

CMOS Multi-Function Analogue Laser Sensor

IL series

CMOS Multi-Function Analogue Laser Sensor IL series

Laser Differentiation Sensor with Extremely Stable Detection

Highly accurate differentiation unaffected by colour or material

IL Series CMOS multi-function analogue laser sensors are reflective laser displacement sensors that provide the best-in-class detection ability and stability at a reasonable cost. Stable detection is possible without tuning for workpiece types or their surface conditions, so the IL Series can be added to production lines to help make setup, changeover, and product changes easier. With a wide-ranging lineup of sensor heads, including high-accuracy models and long-range (up to 3.5 m) models, these laser sensors can be applied to diverse applications thanks to their broad dynamic range and environmental resistance. 1 μm repeatability allows for use in high-tolerance detection setups that previous sensors could not stably provide.

Features

Sharp-Line Sensor Heads

Introducing a new high-performance head for the IL Series Stable performance for the most demanding detection

Multi-Function Amplifier

The multi-function amplifier with an all-in-one design

Lineup

An abundance of head variations for all applications

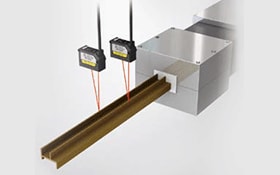

IL Series Multi-function Analogue Laser Sensor Applications

Variety of heads enables abundance of applications