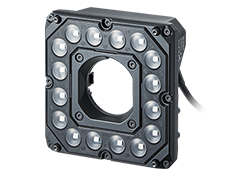

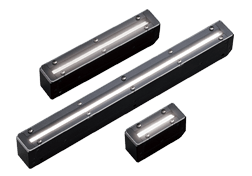

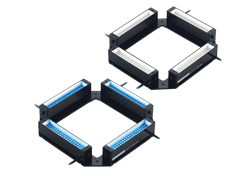

LED Lighting Vision System Peripheral Equipment CA-D Series

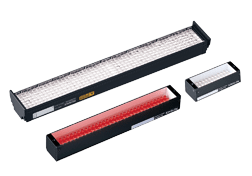

Back LightsFeaturing a variety of sizes and colours to fit any backlit application need

CA-DS

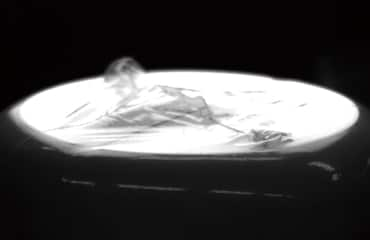

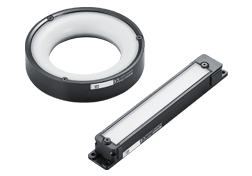

Back light illumination techniques

Standard front lighting can cause inconsistent and low contrast of a target’s features due to shape, colour and surface finish. Using a back light ensures transmission of the light through the target into the camera. If the target is opaque a silhouette is generated creating a strong contrast and outline for stable inspection. Even if a target is transparent it may have a range of densities to it (such as layered material or liquid in a bottle). Contrast can still be achieved through the changes in the absorption and transmission of light in the target.

Camera/light arrangement

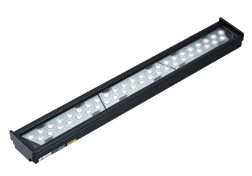

Addition of a large model the size of a piece of A4 paper

A large model the size of a piece of A4 paper has been added to the lineup.

Light is emitted right to the edge of the unit, which makes it possible to install it with the minimum space necessary in terms of the lighting area.

Specially moulding the diffusion plate makes it possible to emit light right to the edge of the diffusion plate.

Application

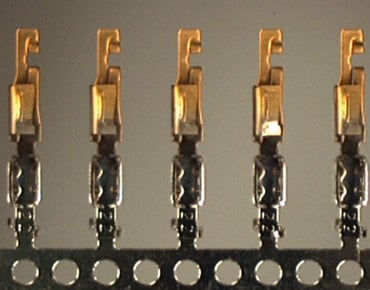

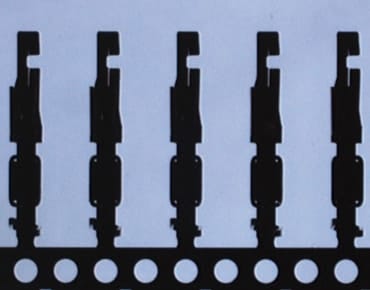

Connector pin strip

With standard lighting

With back light

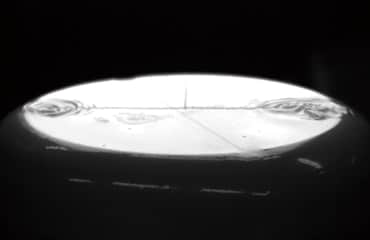

Shrink wrap defect detection

In this application example, the light is used as a specular light with a large lighting area.

Good product:

Defective product: