Examples of countermeasures for product defects

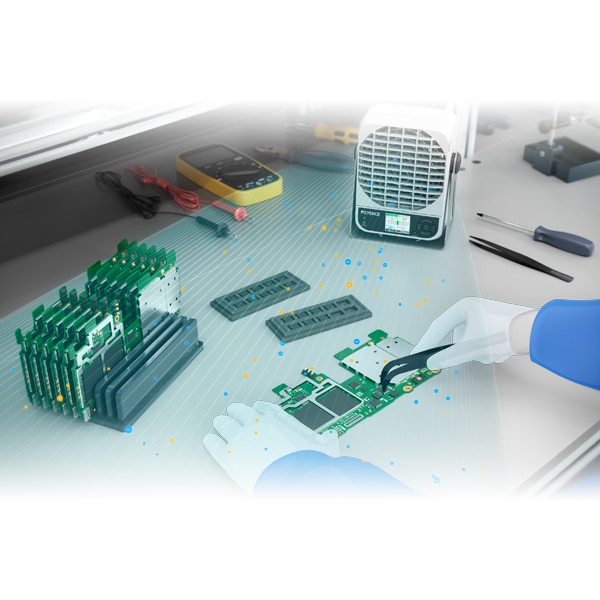

Eliminating static from workspaces

Just one ionizer can be used to eliminate static electricity over a wide area. Processing risks can also be reduced by preventing workers from being able to change the air flow or other settings.

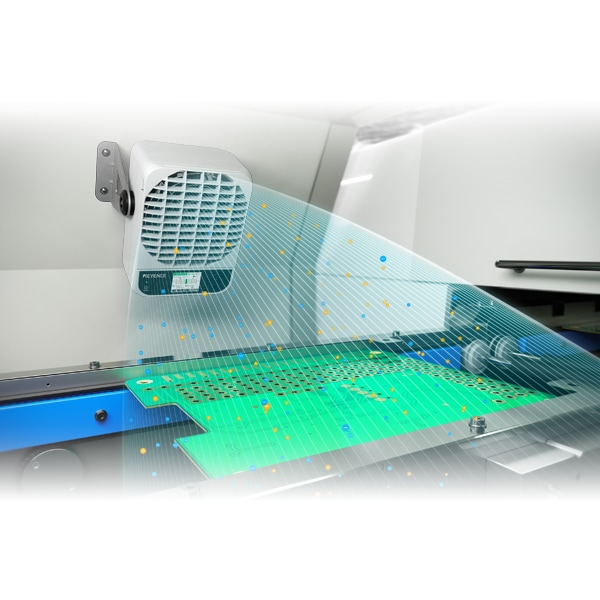

Preventing ESD during PCB inspection and quality assurance

Electrostatic discharge can be prevented during PCB inspection to reduce the risk of defects during product assembly or after shipment even for products that have already passed inspection.

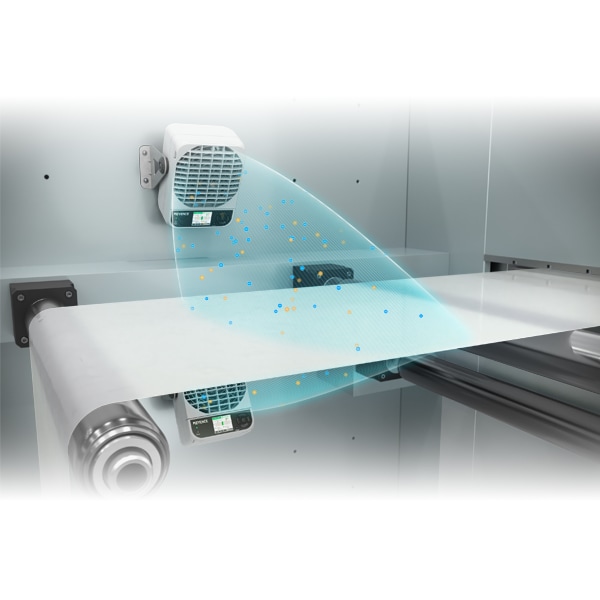

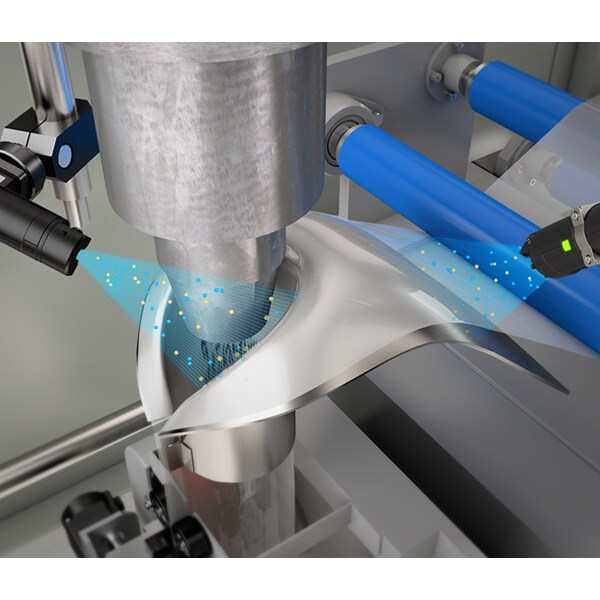

Foreign particle removal before coating

Utilising static elimination with a large air flow makes it possible to remove foreign particles adhered to targets even without a factory air supply.

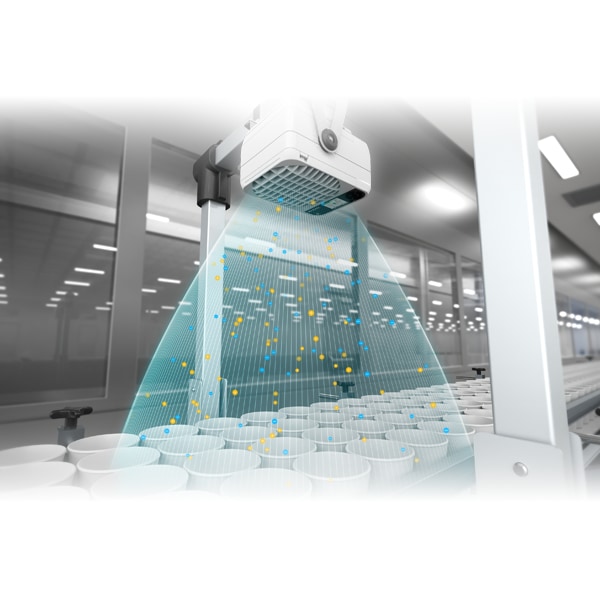

Preventing foreign particles from adhering to food containers

Just one ionizer can be used to eliminate static electricity quickly over a wide area. Constantly monitoring the level of electrostatic charge, which strongly influences the adherence of foreign particles, makes it possible to improve yield rates.

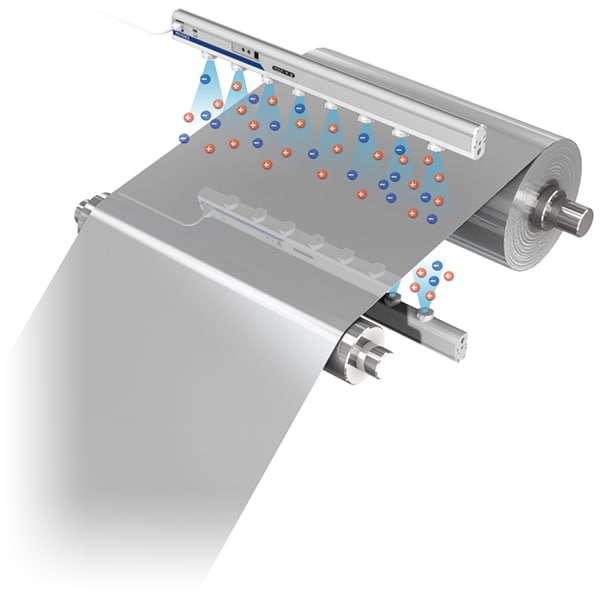

Eliminating static charge during coating

In order to coat the paper with a silicone layer, a very strong electrostatic charge (50 to 100 kV) is generated in the sticker release paper, which can lead to problems such as adhesion of foreign particles, sparking and staff discomfort. An ionizer can eliminate these problems.

Preventing adhesion during heat sealing

Static electricity can cause the contents to stick during heat sealing. An ionizer can prevent these problems before they occur.

For more information, please contact KEYENCE.