Methods for Weld Penetration, Structure Observation, and Defect Analysis

Welding is a technique employed to join metals in a diverse range of fields, including the plant equipment and automotive fields. Weld penetration, base material, and bead may suffer defects caused by stress or corrosion from long-term use. For this reason, it is important to observe and analyse the surface and cross-section of welded parts. This section introduces the methodology, along with observation and analysis examples using our latest 4K digital microscope, that greatly changed the concepts of observation and analysis with conventional microscopes.

- Importance of Weld Penetration Analysis

- Methods for Observing and Analysing Weld Penetration (Metal Structures)

- Latest Examples of Weld Penetration Observation and Analysis

- New Common Practices of Weld Penetration Observation and Analysis

Importance of Weld Penetration Analysis

Among other metal-joining techniques, welding is a rational, airtight fabrication process used in a wide range of applications. Infrastructure, architecture, automobiles, electrical appliances, and electronic devices all employ a variety of welding methods. These different methods, such as variations of arc welding, laser beam welding, and resistance spot welding, are utilised according to purpose and base material.

In particular, process equipment at plants is intended to be used for decades. This requirement demands the highest level of welding quality. There are many types of plants, including thermal power plants; petrochemical plants where new materials are made from petroleum; plants that manufacture general chemicals, drugs, and food; water treatment plants for purifying sewage; and industrial waste disposal plants that carry out recycling processes. All of these plants are enormous facilities that require liquids and gases with different properties and in different states. When ageing or a defect is detected in the welding, observation and analysis of the equipment is crucial for identifying the problem and cause. This is typically not an easy task.

Methods for Observing and Analysing Weld Penetration (Metal Structures)

In the case of large-scale facilities such as plants, micro analysis cannot be performed on the welded structure. However, defects such as poor fusion, slag inclusion, or cracks (stress corrosion cracks and fatigue cracks) in the welded part still require investigation. Therefore, the majority of microscopic observation and analysis of these issues employ the following two types of sample creation methods:

- Microscopic observation of sample filled with resin (embedment)

- The welded part with the defect is cut out as a sample and is filled (embedded) with resin for microscopic observation. Since the sample is cut out, it is possible to observe the cross-section of the weld penetration.

- Microscopic observation by SUMP

- “SUMP” stands for Suzuki’s Universal Micro Printing. If a sample cannot be cut out for microscopic observation, the surface of the sample is transferred to a celluloid plate and is observed using an on-site microscope. The replica samples used for electron microscopy are said to have originated from SUMP.

These observation methods involving the creation of samples are not only used in plants, but also with automobiles, aviation-related equipment, railway vehicles, and ships. In sum, they can be found anywhere welding failures and defects can lead to major accidents. In each case, the metal structure of the welded part is observed and analysed using surface and cross-section observation; along with other techniques.

Latest Examples of Weld Penetration Observation and Analysis

Thanks to technological advancement in recent years, digital microscopes have solved the issues of conventional microscopes, have significantly changed magnification clarity, and have improved workability of samples for the observation and analysis of weld penetration.

KEYENCE’s VHX Series ultra-high definition 4K Digital Microscope adopts the latest high-resolution lenses, 4K CMOS, lighting options, and image processing technology, thereby enabling observation with clear images and rational analysis beyond comparison with conventional microscopes.

Cross-section observation and defect analysis of weld penetration structure

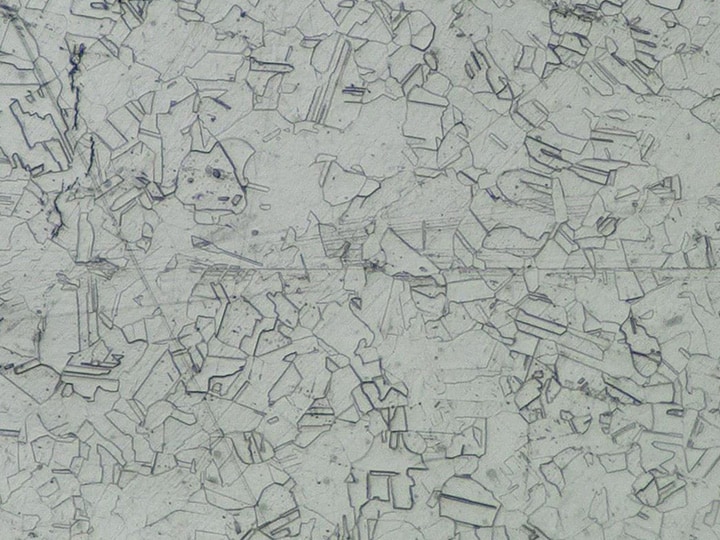

With conventional microscopes, only a part of the metal structure of the weld penetration under observation was in focus, which was why this procedure took a long time. Proficiency was also required to achieve accurate observation and analysis.

The VHX Series 4K Digital Microscope allows for quick and easy capture of fully focused images by using depth composition. These fully-focused images contribute to clear observation of the condition of the metal structure of the weld penetration and of fine cracks in the base material, regardless of the user's skill level, thereby helping to prevent problems from being overlooked.

Weld penetration structure observation using SUMP samples

With conventional microscopes, samples created by SUMP may only partially come into focus due to the need for high-magnification observation. Additionally, replicas have low contrast, which can make observation impossible.

Using clear, high-resolution 4K images, the VHX Series can observe and analyse SUMP samples that have uneven surfaces and low contrast.

Achieving on-site micro analysis with handheld observation

Conventionally, large test targets could not be observed under a microscope on site—the only ways to observe and analyse such targets were to cut out a sample and fill it with resin (embedment) or, if a sample could not be cut out, use SUMP to transfer or create a replica. The accuracy and workability of the investigation were also affected by the quality of the created samples.

The VHX Series 4K Digital Microscope can perform observation and analysis in handheld form, providing clear magnified images produced by the deep depth of field of the dedicated lens. This observation and analysis can eliminate the time, work, and hassle of creating samples as well as enable non-destructive observation and analysis of the actual target on the spot.

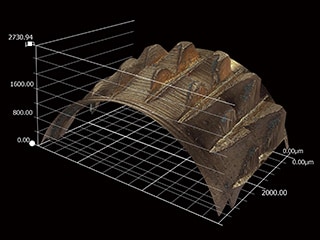

A single unit supports various 2D and 3D measurements

The VHX Series 4K Digital Microscope can not only perform clear magnification and observation, but can also perform measurements and quantification that were not possible with conventional microscopes.

2D and 3D measurements, roughness measurement, technical cleanliness inspection, crystal grain size measurement, and other useful functions for the inspection of metal structures and products can be readily executed from a single machine using easy mouse operations.

New Common Practices of Weld Penetration Observation and Analysis

Observation and analysis of welds and their metal structures are extremely important as these operations closely relate to the safety of various metal products and equipment. Accuracy and speed are required for identifying and analysing problems.

The VHX Series is equipped with many other advanced functions that were not conventionally available. Automatic zoom from 20x to 6000x, multi-lighting functionality, and 2D and 3D measurements contribute to advanced observation and analysis that is not possible with conventional microscopes.

For additional product info or inquiries, click the buttons below.