Observation and Measurement of Springs Using a Digital Microscope

Like screws, springs are frequently used mechanical components used in various devices such as automobiles, electrical products, and daily necessities. This section introduces an overview on springs and introduces observation and measurement examples using a digital microscope.

- Typical spring types

- Compression coil spring materials and dimensions

- Observation and measurement examples of springs using a digital microscope

Typical spring types

Coil springs

- Compression coil springs

-

Compression coil springs generate a repulsive force when loaded in the compression direction. The structure either has an equal pitch or a taper. This type of spring is commonly used as suspension springs in automobiles.

Equal pitch coil spring

Tapered coil spring - Tension coil springs

-

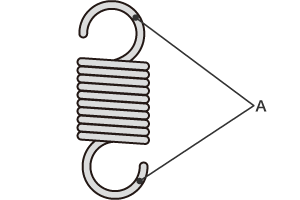

Tension coil springs generate a repulsive force when loaded in the extension direction. Hooks are included on both ends of the spring. This type of spring is commonly used in bicycle stands and measuring devices.

Tension coil spring

- A: Hooks

- Torsion coil springs

-

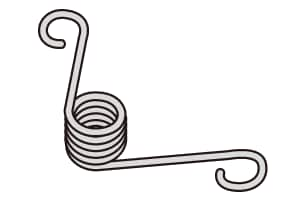

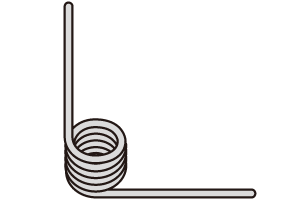

Torsion coil springs generate a repulsive force when the coil is subjected to torsional movement around the spring’s central axis. Hooks may be included on both ends of the spring. This type of spring is commonly used in door locks and hole punches.

Torsion coil spring (with hooks)

Torsion coil spring (without hooks)

Plate springs

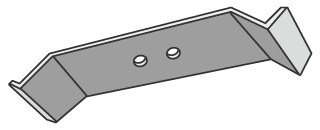

- Flat springs

- Flat springs are the most common type of plate spring and are often referred to simply as plate springs. This type of spring is commonly used in switches.

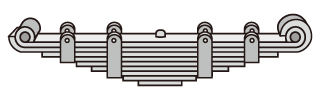

- Overlapping plate springs

- Overlapping plate springs are made of multiple plate springs of different lengths stacked on top of each other. The more layers that are used, the greater durability the spring will have. This type of spring is commonly used as suspension springs for trucks (also referred to as leaf springs).

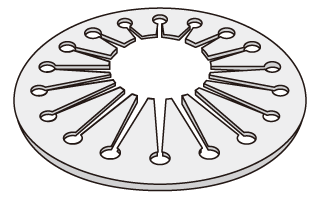

- Coned disc springs

- Coned disc springs are made by hollowing out the centre of a conical plate spring. This type of spring is commonly used as washers to prevent screws from coming loose.

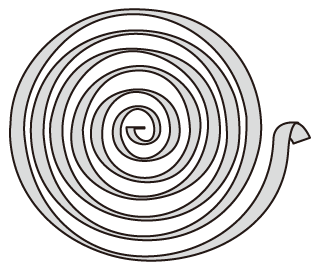

- Spiral springs

- Spiral springs are by winding a plate or strip of material into a spiral shape. This type of spring is commonly used in mechanical watches.

Compression coil spring materials and dimensions

Coil spring materials

- Hardened steel wire

- This is the least expensive of all metal spring materials and is used in various everyday products.

Symbol: SWC - Piano wire

- Offering higher tensile strength than hardened steel wire and greater hardness and fatigue resistance reliability, piano wire is commonly used for industrial springs.

Symbol: SWP - Stainless steel

- Stainless steel offers better corrosion and heat resistance than piano wire, making it a mainstay of coil springs.

Symbol: SUS

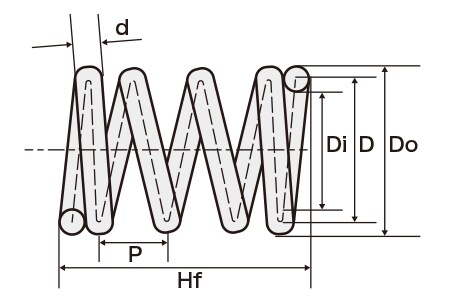

Compression coil spring dimensions

- Dimension description

-

Dimension Description Wire diameter The diameter of the wire used for the spring.

Symbol: d (mm/inch)Average coil diameter The average of the outer and inner coil diameters.

Symbol: D (mm/inch)Outer coil diameter The diameter of the outer edge of the coil.

Symbol: Do (mm/inch)Inner coil diameter The diameter of the inner edge of the coil.

Symbol: Di (mm/inch)Free height The height of the spring with no load.

Symbol: Hf (mm/inch)Active coils The number of coils used by the spring to generate force.

Symbol: NaTotal number of coils The number of all coils between both ends of the spring.

Symbol: NtPitch The distance between the centres of a helically wound wire.

Symbol: P (mm/inch)

Observation and measurement examples of springs using a digital microscope

The latest examples of observation and measurement of springs using KEYENCE’s VHX Series 4K Digital Microscope are introduced below.

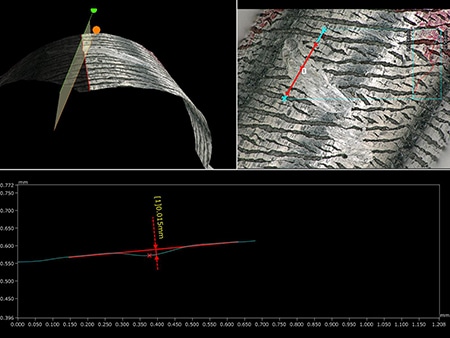

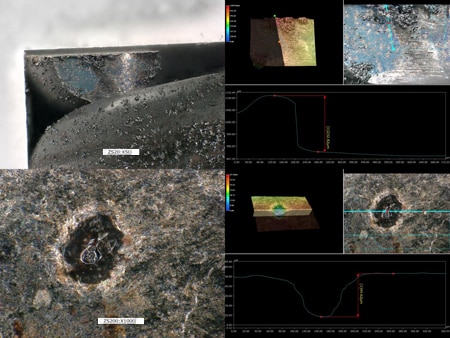

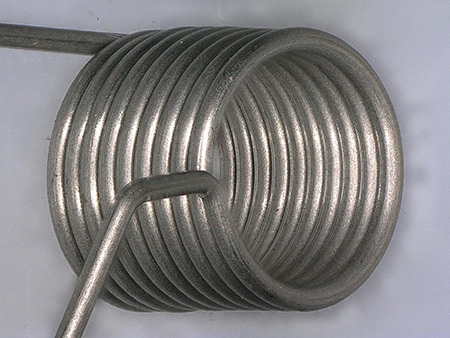

Observation of a coil using depth composition

The depth composition function enables observation of the spring with all coils in focus.

Image after ring-reflection removal

The ring-reflection removal function enables observation with no glare.

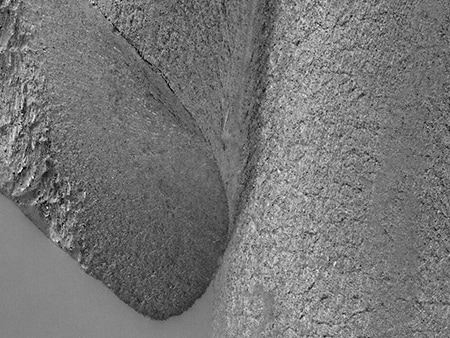

Optical Shadow Effect Mode image

Optical Shadow Effect Mode can be used to visualise detailed surface structures without the need for an SEM.