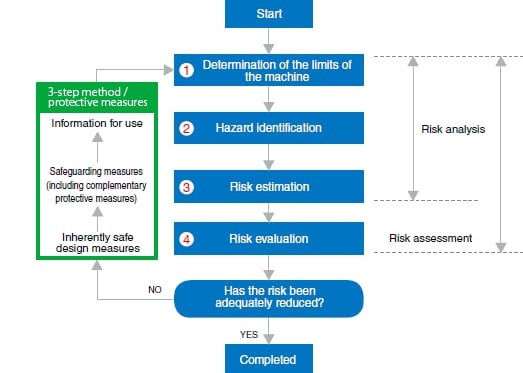

Risk assessment is a method for confirming safety in order to ensure the safety of workers and other individuals and to reduce to the absolute minimum the possibility of harm. Even if harm does not occur, there may exist potential for risk and harm. If these are not addressed, it can be said that the situation possesses a high possibility of industrial accidents occurring. As technology has progressed, a great variety of machines and chemical substances have come to be used, which has led to diversification in the potential for risk and harm. Also, to further reduce industrial accidents, it is necessary to implement safety and sanitation measures in a preemptive, not reactive, manner. The process for carrying out risk assessments is defined by the ISO basic safety standards. The following flowchart shows the risk assessment procedure established by ISO 12100. Generally speaking, safety is confirmed with the following procedure during a risk assessment.

A risk assessment starts with having all the workers understand the risks present at the worksite and the countermeasures for and actual conditions pertaining to said risks. Next, use a reasonable method to determine the priority of the risks that should be eliminated. After that, evaluate if risks for which countermeasures have been implemented have been reduced to tolerable risks. If they have not been reduced to this level, consider what type of protective measures are required. Carry out these activities periodically during the risk assessment and continue it until all risks are reduced to tolerable levels.

First, estimate incorrect usage such as operation mistakes. Limit the specifications of the target machine. Clarify the use limits of the machine such as the purpose of using the machine and the machine's usage conditions.*1 Consider limits such as space limits (installation environment) and time limits.*2, *3 Carry out these steps to determine details such as what kind of machine will be used by what sort of user in what location and for how long.

For example, bring to light the minor incidents that occur during work and machine operation at the factory and identify the causes of risks. Questionnaires for workers, notes regarding dangerous experiences at the worksite, and other such surveys are effective during this activity.

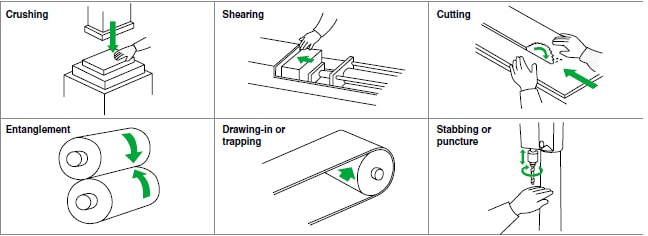

Hazard identification refers to the identification of the causes of hazards. This is the identification of all the various hazards (permanent hazards and hazards that may occur unexpectedly) that may occur due to the machine. Examples of the types of hazards that can be present on machines are shown below.

In addition to those hazards listed above, other possible hazards include electrical hazards, thermal hazards, hazards generated by noise, hazards generated by vibration, hazards generated by radiation, hazards generated by materials and substances, and hazards generated by ignoring ergonomic principles.

A risk occurs when the potential for risk and harm including a hazard comes into contact with a person. For example, when drilling holes in small parts, the hazard is the machine that performs the processing and the person is the worker. The possibility of accidents in which the worker's finger is crushed or cut occurring exists in this work.

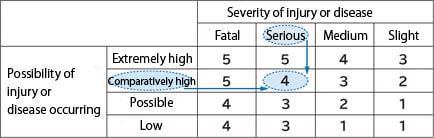

Estimate the degree of risk and the frequency of situations in which risk is present. Averages or subjective values must not be used for the estimate. It must be possible to explain the details of the estimate to the members in a way that they can come to an agreement on the estimate. Also, the result should be expressed as a score or other such numeric value and presented in a format that everyone can share easily. The criteria for the estimate are the severity of injury or disease, the frequency of the risk occurring, and the frequency of people approaching the hazard. Calculate the priority of the countermeasure from the result of considering these criteria.

Example 1: Example of an estimate with a severity value of (2) Serious and a possibility value of (2) Comparatively high

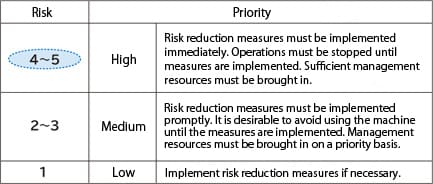

Risk evaluation is the last step of the risk assessment. In this step, risks are evaluated to see whether they have been reduced to tolerable risks. If they have not been reduced to this level, it is necessary to consider what type of protective measures are required.

The detailed method is to determine the risk level by calculating the evaluation score (risk points) on the basis of values such as the severity of injury or disease, the frequency of the risk occurring, and the frequency of people approaching the hazard that were calculated in the risk estimation. In determining the risk level, it is useful to compare values by creating a risk evaluation table or something similar.

Click here for an explanation of the risk reduction method (the 3-step method).