Medical

In the medical industry, it's critical to maintain high standards of quality to comply with the tight tolerances. KEYENCE sensors provide reliable solutions for measurement and inspection of medical devices and drugs to help medical manufacturers deliver products that exceed those standards. Below are some examples of how our sensors can be applied to improve quality and process control.

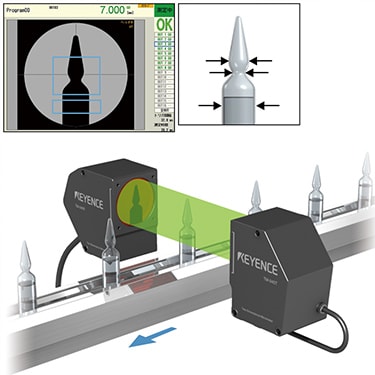

Accurately inspect needle tips inline. The TM-3000 is a calibrated and traceable 2D measurement sensor that can be used for reliable inspection of medical components.

High-speed 2D Optical Micrometer

TM-3000 series

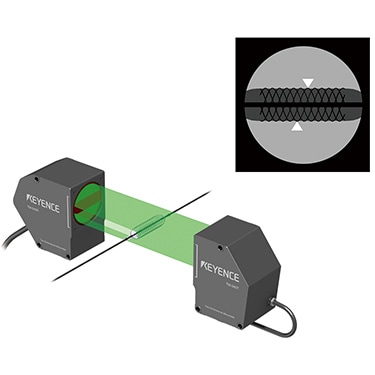

Historically, it's been difficult to inspect dimensions of transparent objects, but the TM Series makes it easy. The factory calibrated, backlit sensor greatly reduces the man-hours required to accurately measure transparent ampoules or vials.

High-speed 2D Optical Micrometer

TM-3000 series

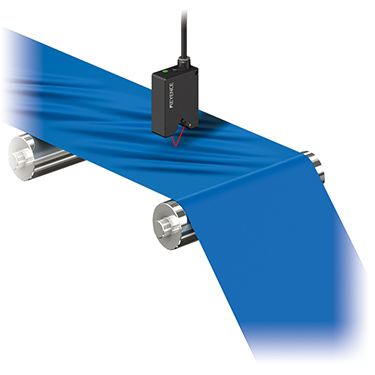

Uniform thickness is important for IV bags. Measuring thickness inline using high precision displacement sensors provides an accurate, non-contact method for checking uniformity.

Ultra High-Speed/High-Accuracy Laser Displacement Sensor

LK-G5000 series

Measure outer diameter of stents without contacting the part. Using a 2D micrometre, you can automatically find the minimum and maximum diameter over an area.

High-speed 2D Optical Micrometer

TM-3000 series

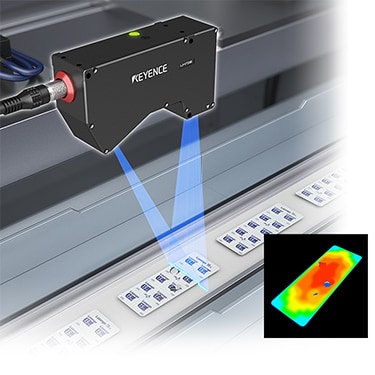

3D inspection of blister packaging enables defection of tears or missing tablets. Using laser profilers allows you to reliably inspect blisters regardless of coluor.

High-speed 2D/3D Laser Profiler

LJ-V7000 series

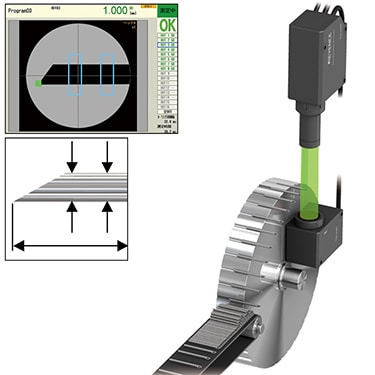

Inspect for mould wear without touching the surface. The CL-3000 is coaxial, making it possible to measure grooves in the mould with high accuracy.

Confocal Displacement Sensor

CL-3000 series